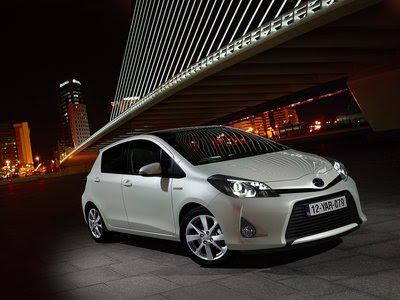

2013 Toyota YarisThe new Toyota Yaris Hybrid is the primary full hybrid vehicle to go on sale within the European B-segment. The Yaris model range flagship, it represents a new and unique provide in Europe's highest sales volume section, and will bring the advantages of full hybrid technology to a wider range of customers than ever before.

The Yaris is Toyota's best-selling core model in Europe, with more than 2.5 million units sold. It is the sole B-section automobile to supply customers the selection of three different powertrain varieties - full hybrid, diesel or petrol.

Combining the ingenious packaging and concrete agility of the Yaris model vary with the unique driving experience and potency of Toyota's Hybrid Synergy Drive® (HSD), the Toyota Yaris Hybrid is a new major step in the company's full hybrid European roll-out strategy.

With low fuel consumption, low environmental impact, robust acceleration, great manoeuvrability and unique EV capabilities, it represents the final urban car.

The new powertrain has been optimised for installation among the vehicle's compact, very efficient packaging style, without detriment to either system quality and performance, or passenger accommodation and loadspace. The downsized hybrid system combines a substantially re-engineered one.5 litre petrol engine with a lighter, more compact electrical motor, transaxle, inverter and battery pack.

The highly economical powertrain offers the most effective balance of performance and fuel consumption/CO2 emissions within the B segment. It delivers an average fuel consumption of just three.five l/100 km and segment-best CO2 emissions of only 79 g/km, whilst allowing customers frequent, all-electrical driving periods that emit no NOx, PM or CO2 emissions.

With phase-best fuel consumption of three.1 l/100 km within the urban cycle, the Toyota Yaris Hybrid represents the ideal urban mobility alternative at a time when fuel prices are reaching peak levels. Internal test data show that a high proportion of journey time and distance will be undertaken with the engine off, representing important advantages in fuel consumption.

Expected to represent twentypercent of all Yaris model sales in Europe, the Toyota Yaris Hybrid isn't a distinct segment model. Rather, it represents a brand new, distinctive different for demanding urban drivers who expect a new driving and ownership experience from their automotive.

The Toyota Yaris Hybrid combines the tangible benefits of advanced technology, low emissions and unbeatable value of possession with a brand new, uniquely relaxed and quiet driving vogue. Its HSD system proves that driving pleasure wants not to be compromised by environmental responsibility and low running costs, and it shares the traditionally high residual values of all Toyota Hybrids.

With Toyota Motor Producing UK (TMUK) already assembling Toyota full hybrid vehicles, the start of Yaris Hybrid production at Toyota Motor Producing France (TMMF) makes Toyota the only manufacturer to have 2 full hybrid technology production facilities in Europe, reinforcing the corporate's commitment to native, advanced technology manufacturing in Europe.

Following the launch of the Auris Hybrid, the Yaris Hybrid is Toyota's second core model to feature HSD technology. From 2012, the Toyota hybrid vary can feature 5 models: the Yaris Hybrid, the Auris Hybrid, the Prius, the Prius+ and the Prius Plug-in Hybrid.

A more aspirational style for the most efficient package in the section

At its original launch, the Yaris quickly became nicknamed "Piccolo Genio" (Very little Genius). This may be a testament to a car which has been developed over successive generations in accordance with the key concept of "compact outside while roomy within", consistently setting new standards in packaging ingenuity.

The Toyota Yaris Hybrid inherits all the clever DNA of the quality, third generation model, offering B section customers a creative combination of tiny, compact packaging and a spacious, practical interior.

The Toyota Yaris Hybrid differentiates itself from the other Yaris derivatives with an exclusive, aerodynamically efficient exterior design which instantly identifies it because the flagship of the Yaris model vary.

It combines a replacement, a lot of aggressive, Under Priority frontal design part - the distinctive new Toyota face style execution, with a Keen Look detailing reinforced by hybrid-specific LED lights.

Flanked by aerodynamically economical front aero corner treatments, the robust centre section of the lower bumper houses a larger, trapezoidal lower grille optimising engine bay cooling while emphasise the new hybrid's ground-hugging stance and low centre of gravity.

A slimmer higher grille, elegantly sculpted to highlight the hybrid-blue Toyota badge, is flanked by slim, Keen Look headlights which emphasise the new hybrid's bold, horizontal front styling. Exclusive to the Toyota Yaris Hybrid, the projector-kind headlamp unit features commonplace chrome-plated 'eyebrows' lipped with an LED 'lightguide', and LED Daytime Running Lights (DRL).

In profile, identified by hybrid badging and exclusive wheel designs, the new hybrid shares the stylish, cab-forward silhouette and long wheelbase profile of the standard Yaris. The exterior overall length is solely twenty mm longer than the quality Yaris.

To the rear, the hybrid-blue badged tailgate incorporates a replacement, LED-sort high mounted stop lightweight, and clear lens combination lights incorporate a LED tail and stop lamp signature distinctive to the new Yaris Hybrid.

The Toyota Yaris Hybrid is obtainable with a choice of unique 15" and sixteen" aerodynamic wheels, and a vary of eight body colors as well as a model-specific new Pearl White finish execution.

Toyota pioneered this Pearl White finish, that has needed the introduction of a bespoke production method at the TMMF plant where the new hybrid is constructed. Reinforcing the Toyota Yaris Hybrid's uniquely trendy and environmentally-conscientious style credentials, the new colour delivers a cool, prime quality image (notably in sunlight) when the soft, silken lustre of pearl is at its strongest.

On board, Toyota Yaris Hybrid customers profit from a driver-focused cockpit with hybrid-exclusive details and trim finishes.

Silver ring-cut 3 dimensional instrument dials incorporate a hybrid system indicator and feature a mix of white and blue backlighting. The centre console-mounted Toyota Touch system incorporates a hybrid energy monitor illuminated in blue as well as the twin zone air-conditioning.

The dashboard soft-touch pads and front door trims are finished in an exclusive, Ice Grey colour, and blue stitching trims the leather upholstery, steering wheel and hand brake. A distinctive gear lever to the hybrid spinoff comes standard with blue end on the gear knob.

Downsized full hybrid powertrain for fuel and space potency

The new Yaris Hybrid introduces the first downsizing of Toyota's proven Hybrid Synergy Drive® (HSD) technology. It represents a important engineering breakthrough within the packaging of the full hybrid powertrain.

The new powertrain has been optimised for installation among the vehicle's compact, extraordinarily efficient packaging style, while not detriment to either system quality and performance, or passenger accommodation and load house.

Every key HSD part has been contracted and weight, and each the fuel tank and battery are installed below the rear seat. As a result, the Toyota Yaris Hybrid maintains identical occupant space and the identical 286 litre baggage capability as that of the quality model.

The downsized full hybrid system combines a 1.5 litre petrol engine unit with a lighter, more compact electric motor, transaxle, inverter and battery pack. The entire system weight is 201 kg, 20% (42 kg) but that of an Auris Hybrid.

Compact, Lower Displacement Petrol Engine

The 1,497 cc, 16 valve, DOHC Atkinson Cycle petrol engine with VVT-i is predicated on the engine block of the second generation Prius, but has been fully re-designed. It is 50 mm shorter and seventeen kg lighter than the one.eight litre unit of existing Toyota full hybrid powertrains, equating to a 10percent reduction in length and a 17% reduction in weight.

The new engine generates a maximum 55 kW/74 DIN hp at 4,800 rpm and maximum torque of 111 Nm from 3,600 to 4,400 rpm. With a focus on lower emissions and also the minimisation of mechanical friction for improved fuel efficiency, some 70% of all engine elements are either new or redesigned.

Overall, the thermal potency of the Toyota Yaris Hybrid petrol engine has been improved by 6% over that of the second generation Prius, contributing to enhancements in both fuel potency and environmental performance.

Newly adopted engine technologies embody a cooled Exhaust Gas Recirculation (EGR) system, an electric water pump, the elimination of the auxiliary drive belt, a coffee-friction timing chain, a light-weight, resin-based mostly intake manifold and a compact exhaust manifold.

When used in combined with a cooled EGR system, the Atkinson cycle engine offers vital gains in fuel potency and the reduction of emissions.

In the Atkinson cycle, compression and growth are asymmetrical, and the inlet valves close late, delaying compression. This creates a high enlargement ratio for fewer compression, converting combustion energy to engine power additional effectively. As a result, the exhaust temperature is lower than that of conventional engines. The cooled EGR system reintroduces cooled exhaust gas into the intake system, any reducing engine operating temperatures.

Allied to a tiny, lightweight, multi-perform radiator, the adoption of an electrical water pump both enhances engine warm-up performance and reduces cooling friction loss, improving fuel potency. The elimination of a mechanical pump drive belt reduces friction, further improving fuel economy.

A brand new, a lot of compact, hybrid-exclusive resin-primarily based intake manifold combines lightweight weight with improved quietness through the reduction of both vibration and noise. And the employment of highly efficient, twelve-hole atomizing fuel injectors reduces both fuel consumption and emissions.

The exhaust system features a replacement, low heat capacity, maniverter-sort exhaust manifold. By positioning the catalytic converter abundant closer to the engine exhaust port, it decreases the catalyser warm-up time by twenty fourpercent and contributes to a marked improvement in emissions throughout shorter journeys.

Downsized Hybrid Transaxle

Housing the electric motor, generator, power split device and double-motor reduction mechanism in one light-weight, highly compact transmission casing directly comparable in size to that of a typical gearbox, a brand new transaxle lies at the center of the Hybrid Synergy Drive® system.

The employment of a smaller E-CVT electrical continuously variable transmission and a more compact electrical motor effects a half dozen% reduction within the length of the Toyota Yaris Hybrid's hybrid transaxle and an eleven kg weight saving over that of the Auris Hybrid, creating the most compact hybrid transmission nonetheless built by Toyota.

Generating an immediate maximum of 45 kW and 169 Nm torque during acceleration, the new electric motor has been made smaller and lighter through the optimisation of the magnet material, and therefore the winding of the coils with flat, instead of round, wire. The motor cooling structure has additionally been improved, allowing for a smaller, yet a lot of economical and powerful motor.

The transaxle currently incorporates a multifunctional motor reduction gear at intervals the facility division mechanism, and a brand new gear deceleration mechanism abolishes the utilization of chains.

Gear tooth grinding and shaving technology similar to that used on the Auris Hybrid effects a notable reduction in transmission noise and vibration. This is more lowered by the adoption of a newly designed torsional vibration damper. Its smaller diameter created attainable by the utilization of a three spring structure. The new, lightweight damper helps suppress the transmission of engine vibrations to a minimum level.

The optimisation of lubrication each improves transaxle potency and minimises energy losses. A brand new lubrication mechanism is adopted, in that each gear and bearing is lubricated by combing up the Automatic Transmission Fluid (ATF) with the rotation of the final driven gear and counter driven gear, reducing driving force losses.

The utilization of a split construction oil catch tank that provides oil for each the motor/generator and kit lubrication lowers the dynamic oil level, reducing agitation losses.

Additional Compact Hybrid Battery

The new, downsized full hybrid powertrain conjointly features a smaller, fourteen4 V nickel-metal hydride battery with a more economical vehicle electrical power management system.

The number of cells has been reduced from the 168 of the current, Auris Hybrid battery to solely one hundred twenty, composed of 20 modules connected in series. This effects a decrease in volume of 20p.c and a weight saving of 11 kg, permitting for the installation of the new battery entirely beneath the rear passenger seats, with no intrusion into the cargo loadspace.

In addition to the present reduction in size and weight, battery charging efficiency has been improved, and also the pack state-of-charge recovery time has been decreased by sixty sevenpercent compared to that of the Auris Hybrid.

New Power Management Unit with Smaller Inverter and Converter

Because of a reduction in hybrid system current and voltage, the system's Power Control Unit has also been created smaller and lighter through the development of a additional compact inverter and switching unit.

Smaller and lighter than that fitted to the Auris Hybrid, the new inverter features a newly structured capacitor, reduced energy losses and improved cooling, enhancing fuel efficiency.

By optimising the layout of internal elements, the scale and weight of the DC-DC converter have also been reduced. And the composition of the noise filter has been revised to reinforce unit quietness.

Compared to the Auris Hybrid, unit output current has been reduced from a hundred and twenty to eighty A and output voltage lowered from 650 to 520 V, saving system energy with no loss of performance or potency.

Hybrid System Performance

Combining the ability of a 55 kW petrol engine and battery powering the electrical motor, the Toyota Yaris Hybrid's highly efficient powertrain generates a most seventy four kW/one hundred DIN hp system output. It offers the best balance of performance and fuel consumption/CO2 emissions within the B segment.

The Toyota Yaris Hybrid can accelerate seamlessly from 0-100 km/h in 11.8 seconds, and on to a most speed of 165 km/h. Conversely, it delivers a mean fuel consumption of just three.five l/100 km and section-best CO2 emissions of only 79 g/km, whilst permitting customers frequent driving in modes that emit zero NOx, PM or CO2 emissions. Its exceptional fuel efficiency offers the Yaris Hybrid a driving range of one,00zero km on a single tank of fuel.

Hybrid Synergy Drive in Operation

Over the course of any journey, Toyota's Hybrid Synergy Drive® system operates in many different modes to maximise the Toyota Yaris Hybrid's' overall efficiency. At rest, the engine stops automatically to avoid wasting fuel. Below operating conditions of low engine potency like begin up and low to mid-vary speeds, the vehicle runs on the electric motor alone, so eradicating CO2, NOx and PM emissions.

Under normal driving conditions, power allocation is constantly adjusted between engine and electric motor to mix optimum performance with maximum fuel efficiency.

Via an Electronically Controlled Braking system, the electrical motor acts as a high-output generator throughout deceleration and below braking to impact regenerative braking, optimising energy management in the Hybrid Synergy Drive® system by recovering kinetic energy (normally wasted as heat underneath braking and deceleration) as electrical energy for storage in the high performance battery.

Well balanced dynamics, ideal for city driving

Building on the inherently quiet, swish power delivery of Toyota's Hybrid Synergy Drive®, the basic parts of intrinsic driving pleasure - like acceleration/braking feel, balance and agility - are totally refined while not any compromise in the new Yaris Hybrid.

Toyota's engineers have undertaken exhaustive testing to make sure the new Toyota Yaris Hybrid's dynamic talents will meet client expectations in the least vehicle speeds and in all driving scenarios.

Full Hybrid in operation

Recent globe tests with Toyota's Hybrid Synergy Drive powertrain reveal that the Yaris Hybrid zero emissions driving accounts for around sixty six% of the common commuter journey length and around 58% of the full journey time, with the petrol engine being changed.

The electric motor's ability to deliver maximum torque from the vehicle acceleration start provides important benefits throughout the stop/start driving of urban traffic conditions, combining brisk acceleration from a standstill in close to silence with category-leading acceleration underneath full throttle of 0-fifty km/h in only 4 seconds.

The new Toyota Yaris Hybrid's seamless, E-CVT electrical continuously variable transmission benefits from a brand new management system to form a a lot of progressive engine rpm increase during vehicle acceleration. Optimised at seventy-90p.c throttle opening, the new system suppresses excessive increases in engine rpm below acceleration, giving drivers a a lot of natural-feeling, linear relationship between vehicle and engine speeds.

Supplementing this enhanced E-CVT transmission, 2 alternative 'on-demand' drive modes may be selected to additional increase driving efficiency, performance and fuel economy.

From start-up and at speeds up to 50 km/h the new Yaris Hybrid automatically operates in EV mode, driving under electric motor power alone. The driver might also select EV mode manually. This distinctive driving mode is only out there to drivers of full hybrid vehicles.

With vehicle vary dictated by battery charge, the EV drive mode allows for urban driving with minimal noise and zero CO2, NOx and PM emissions for up to two kilometres. Because the petrol engine is converted throughout its operation, the EV drive mode contributes to a important reduction in the Toyota Yaris Hybrid's overall fuel consumption.

In ECO mode, throttle response to aggressive accelerator pedal inputs is reduced and air-conditioning control optimized for improved fuel economy. Depending on driving conditions, the ECO mode can facilitate drivers achieve regarding 10percent reduction in fuel consumption versus the traditional mode.

Optimum Weight Distribution for Balanced Driveability

The in depth use of high-tensile steel at intervals the new Yaris Hybrid's construction not only saves weight, however also offers bigger bodyshell rigidity for handling stability. Some fiftyp.c by weight of the body is made in high-tensile steel, allowing for weight reduction with no loss of torsional stiffness.

With an unchanged a pair of,510 mm length wheelbase, the front overhang has been increased by just twenty mm to accommodate the downsized full hybrid powertrain. With each the fuel tank and therefore the new, additional compact hybrid battery located well inside the vehicle wheelbase and as low as potential, the new Toyota Yaris Hybrid combines a particularly low, 550 mm centre of gravity with 63:thirty seven front/rear weight distribution to deliver well-balanced driveability.

Enhanced Aerodynamics for Class-leading Drag Coefficient

Aerodynamic potency is prime to fuel potency, vehicle stability and quiet running, and each part of the new Yaris Hybrid's bodywork has been styled to optimise airflow and minimise drag.

Sized to optimise hybrid powertrain cooling, each upper and lower front grilles have been carefully shaped to both swish and minimise the intake of air into the engine bay.

The profiles of the front bumper aero corners, bonnet, steeply raked A pillar, door mirrors, roofline, rear spoiler, rear bumper aero corners, the rear combination lamps and even the wheels have all been designed to maximise the Toyota Yaris Hybrid's aerodynamic efficiency.

As well, numerous underbody airflow rectification components have been adopted to make a flat surface, smoothing the flow of air beneath the new Yaris Hybrid. These embody a front spoiler, a large engine undercover, and front, centre and rear spats. A rear undercover incorporates vertical fins that produce a laminar flow impact to enhance ride stability.

As a result, Toyota's new full hybrid boasts a class-leading drag coefficient of just Cd 0.286.

Agile Handling and Responsive Steering

The new Yaris Hybrid shares the standard Yaris' proven combination of MacPherson strut front and torsion beam rear suspension. Modifications to both spring and damper rates are optimised based mostly on the new full hybrid's weight distribution.

The independent, MacPherson strut front suspension shares the mass and vibration reduction measures introduced on the quality Yaris, optimising the system's road tracking performance and minimising vibration whilst delivering applicable ride comfort, driving safety, agility and grip.

The rear torsion beam suspension also edges from the mass reduction measures and system enhancements introduced on the quality Yaris, once again reducing vibration and enhancing ride comfort, while improving vehicle agility.

The Toyota Yaris Hybrid options a fast steering gear ratio of fifty six mm/rev to deliver a better steering feel and vehicle response. The bearing rigidity of the rack and pinion gearing reduces friction and system play, any enhancing accuracy and feel. The vehicle features a category-leading turning circle of only four.7, permitting for nice manoeuvrability in congested town streets or while parking.

Powerful Regenerative Braking and Low Rolling Resistance Tyres

Incorporating Electronic Brakeforce distribution (EBD) and Brake Assist, Traction Management (TRC) and Vehicle Stability Management (VSC), the new Yaris Hybrid is equipped with an Electronically Controlled Braking (ECB) system that coordinates the control of each hydraulic and regenerative braking.

The new full hybrid is fitted with ventilated disc brakes to the front and solid, discs to the rear for powerful, progressive and well balanced braking potency.

Coordinated control of the hydraulic and regenerative braking systems maximises the regeneration of energy by the electric motor during deceleration and below braking.

Fuel efficient tyres provide ultra-low rolling resistance and enough levels of grip, while their reduced vertical stiffness further improves ride comfort.

An unbeatable worth proposition in the B-section

Its segment-1st, full hybrid technology offers Toyota Yaris Hybrid customers outstanding price for cash through an unparalleled combination of competitive price, low maintenance and running costs, and high residual values.

The Yaris Hybrid is competitively priced within the segment, comparing significantly favourably against diesel powered vehicles. However, customer convenience isn't compromised, with features such as twin auto-air-conditioning, automatic transmission, full electrical drive and stop and begin fitted as standard across the model vary.

Best-in-class CO2 emissions of 79 gr/km combined with superior fuel potency provide customers exceptionally low running prices and, in several countries, vital tax incentives or benefits.

The Toyota full hybrid consumes only 3.five l/a hundred km over the European homologation combined cycle, allowing customers to drive up to one,000 km on one tank of fuel. At simply 3.1 l/one hundred km, the urban cycle homologation fuel consumption is that the lowest within the section, contributing to more town driving fuel savings.

The Hybrid Synergy Drive® system has been specifically designed for low maintenance and outstanding sturdiness. The powertrain has been designed with no requirement for the clutch, starter motor, alternator belt and timing belt traditionally employed in other vehicles. With no need to either service or replace these parts, customers will realise a saving of around 1,5001 Euro over 100,000 km.

And, due to the efficiency of the Toyota Yaris Hybrid's Electronically Controlled Braking system (ECB), the brake pads life expectancy will reach 100,00zero km.

Combining this element longevity with reduced labour times during servicing, Yaris Hybrid maintenance prices over 100,000 km are expected to be amongst very cheap in the B section, realising an extra saving of around 1,000 Euro.

Rigorously assessed for performance and sturdiness, and secured by over fourteen years of in-service expertise, the complete hybrid battery is designed to last the entire life of the car.

The new Yaris Hybrid edges from a 3 year/one hundred,00zero km warranty, extended to five years/a hundred,000 km on hybrid system components. Warranty data from the Prius and Auris Hybrid has already confirmed the outstanding reliability of the Hybrid Synergy Drive® powertrain.

Hybrid reliability has conjointly been confirmed by the Prius' consistent high ranking in each the JD Power 'Lowest Problems' survey and therefore the TüV quality report.

Initial residual value forecasts for a 3-year amount and 60,000 km already award the Toyota Yaris Hybrid best-in-class status in Germany (51%) and UK (41%). With both Prius and therefore the Auris Hybrid additionally rating highly in their respective classes, this reinforces the high levels of confidence customers place in Toyota full hybrid powered vehicles.

Environmental performance without compromise on comfort or convenience

Priced to be strongly competitive against rival B segment diesel vehicles, the new Yaris Hybrid can be out there in a very selection of two grades - Active and Style.

The new Toyota Yaris Hybrid vary offers customers outstanding price for cash, even without the low-CO2 incentives and tax edges that are offered in several markets. It combines an extremely generous commonplace equipment specification with the added value of Toyota's unique, full hybrid powertrain driving experience.

The Active grade is fitted, as customary, with a smooth E-CVT transmission ideal for the urban environment. An all-electrical EV driving mode, a Stop and Begin system and a Hill Hold Assist operate further reinforce the ease, simplicity and relaxation of the total hybrid powertrain driving vogue.

Steering wheel-mounted audio and Bluetooth switchgear, front power windows, LED Daytime Running Lights (DRL), driver's seat height adjustment, hybrid-blue stitching to the upholstery, dual zone automatic air-con and also the Toyota Touch on-board multimedia system also are fitted as normal from the Active grade.

Toyota Bit may be a 6.1 in., full colour, touch screen interface that represents an inexpensive approach to on-board multimedia systems. It incorporates an AM/FM radio, a CD/MP3 player, Bluetooth movable connectivity with a music streaming facility and automatic phonebook synchronisation at every connection.

A USB port allows for the affiliation of transportable music players, with the facility to display iTunes album cowl art. Also, the system incorporates a rear view camera. The image is displayed on the complete-colour screen when reverse gear is engaged, to assist with parking manoeuvres.

Specific to the Yaris Hybrid, Toyota Touch also incorporates a Hybrid Energy Monitor which displays the important-time energy flow within the Hybrid Synergy Drive system. Vehicle data displays include remaining fuel vary, instant fuel consumption, average fuel consumption per minute over the last 15 minutes and time elapsed since last engine start. The system is accessible in seven languages - French, English, German, Italian, Spanish, Dutch and Russian.

To the great standard equipment of the Active grade, the Style grade adds front fog lamps with chrome ring surrounds, smart entry with push begin, front armrest and 16'' alloy wheels.

Optional equipment for both Active and Vogue grades includes privacy glass, an 8-speaker premium sound system, cruise control and a full length panoramic sunroof.

The Toyota Yaris Hybrid is equipped, as commonplace, with seven airbags, an Anti-lock Braking System (ABS), Electronic Brakeforce Distribution (EBD), Corner Stability Control, (CSC), Brake Assist (BA), Traction Management (TRC) and Vehicle Stability Control (VSC), offering customers the best levels of safety. In 201one, the Yaris was awarded the most five-star Euro NCAP rating.

Toyota Touch & Go

Building on Toyota Bit, Toyota Bit & Go equips the new Yaris Hybrid with the simplest value for money navigation system on the market.

The system includes all the most standard navigation functions, such as advanced traffic coverage, customisable speed limits, speed camera warnings and motorway signposting. It not solely offers drivers a choice of the fastest or shortest route to their destination, however conjointly the one with the tiniest environmental impact - an 'Ecological' route option.

Using a compatible mobile, via Bluetooth, the system offers on-board connectivity to a Google Local Search perform -the biggest and most recent search database in the planet. Via Google Maps, destinations could be input remotely from home or workplace, and Points of Interest may be downloaded for entry as destinations.

The installation of Touch & Go conjointly upgrades the multimedia base unit with the addition of an SMS on-screen send/receive operate incorporating a contact person image display, and a USB-based photo viewing operate.

Many Touch & Go Apps are offered for download like Park &Go, fuel worth data, weather details and parking space info.

TMMF manufactures the only full hybrid within the B-phase

Originally conceived as a highly compact plant -with limited parts stock and an optimised production line layout contributing to a notably streamlined producing process- Toyota Motor Manufacturing France (TMMF) has been building the Yaris for over a decade.

The Yaris has already established a reputation for outstanding levels of Quality, Sturdiness and Reliability. With the addition of additional derivatives including the new Toyota Yaris Hybrid, TMMF remains committed to delivering vehicles with the highest levels of designed-in quality within the B-section.

Yaris Hybrid producing has introduced any complexity and new challenges to the assembly process, and increased the range of Yaris models created on the same line to a record high of 62 varieties at TMMF.

On average, each Yaris requires the assembly of over a pair of,60zero elements, with around 80p.c of total elements common to the standard Yaris and also the Yaris Hybrid. But, there are four hundred new, hybrid-specific components, and forty% of all assembly processes for the Toyota Yaris Hybrid are either new, or required adaptation. As a result of of the plant's terribly compact size, stock management has had to be any optimised, and sequenced delivery organised for a bigger variety of elements.

Over 4,000 hours of Yaris Hybrid assembly training was provided to TMMF members, with a concentrate on three key areas: assembly techniques for new on-line parts, part variety recognition amongst elements of an analogous kind, and the meeting of key quality targets. Specific attention was paid to the inverter assembly, this element being highly sensitive to mud and body intrusion.

Specific safety coaching in the way to handle high voltage components was provided to some fifty plant members, and new safety procedures resultant from the silent running of vehicles in EV drive mode established. Similarly, a brand new, hybrid-specific, top quality pearl white paint finish was introduced at TMMF for the primary time.

Despite these changes, and additional logistic complexities like sequencing delivery of a better number of elements, the continuous Kaizen and production line streamlining inherent within the principles of the Toyota Production System have meant that, overall, the Toyota Yaris Hybrid takes not a lot of longer to provide than the standard Yaris.

Befitting the Yaris Hybrid's environmental credentials, the TMMF plant itself has seen the recent implementation of diverse environmental initiatives to minimise waste and lower power and water consumption.

Waste production has been reduced by 34p.c over the last 10 years, and since 2007, 100p.c of waste is recycled or recovered.

Through Toyota's continuous improvement activities, the plant has additionally achieved average savings per automobile of 27% in energy, sixty seven% in water and forty eightpercent in VOC (the volatile organic compounds made through solvent usage) over the identical period.

In 2011, 60p.c of the plant's total water wants were lined by either rainwater - collected in a specific six,200 m3 basin, or by recycling used water from production processes at an in-house waste water treatment station.

A 1,020 m2 photovoltaic membrane has been put in on the plant roof, providing [*fr1] of the electricity needed for the administration building. And therefore the press look incorporates a four hundred m2 solar wall, pre-heating the outside air to avoid wasting on heating energy and CO2 emissions.

Dispensing with the need for packaging materials, all automobile elements are delivered from suppliers to the plant in 400,000 reusable plastic boxes, reused for over ten years.

With TMUK already assembling the complete hybrid Auris, the beginning of Yaris Hybrid production at TMMF makes Toyota the only manufacturer to own 2 full hybrid technology production facilities in Europe, reinforcing the corporate's commitment to native producing of high technology vehicles.

The plant currently manufactures around one,00zero cars each day, corresponding to one new Yaris driving out of the line every sixty eight seconds. TMMF expects to provide around 200,000 vehicles in 2012, of which 25 p.c hybrid.

2013 Toyota Yaris 2013 Toyota Yaris 2013 Toyota Yaris 2013 Toyota Yaris 2013 Toyota Yaris 2013 Toyota Yaris 2013 Toyota Yaris

.jpg)

.jpg)